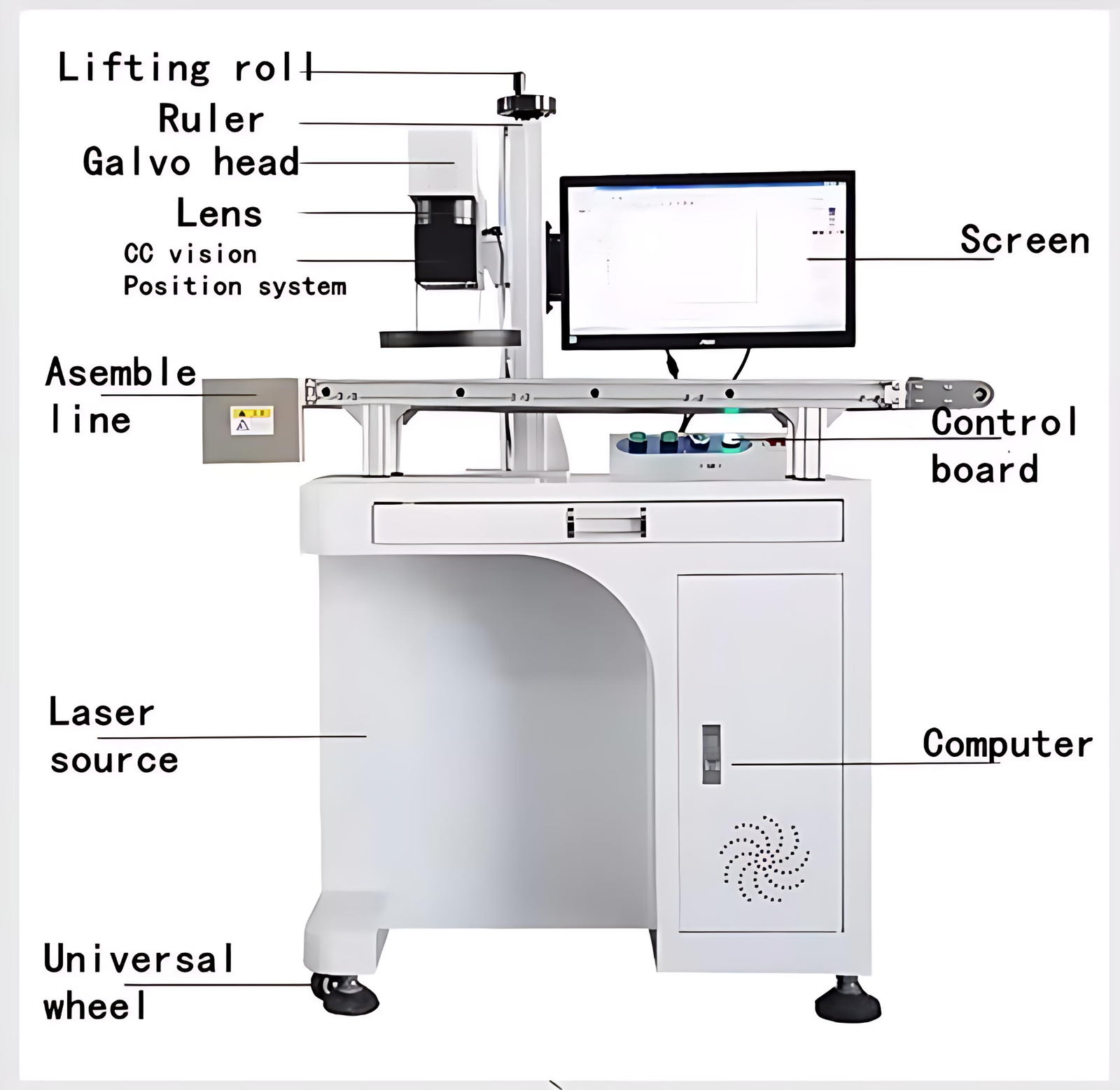

1. Adopting high-precision visual positioning system, precise position and fast corresponding speed.

2. CCD visual positioning system supports mainstream lasers such as ultraviolet, optical fiber, CO2, etc., and is suitable for marking products with a variety of materials.

3. Any position, any angle, and any number of products, the visual positioning system automatically recognizes, automatically detects and locates, and automatically marks.

4. Dedicated precision synchronous conveyor belt supports stepping mode and photoelectric induction mode, which can be switched as required.

5. Visual positioning software system, after years of optimization and verification, the interface is more friendly and easy to operate.

6. The conveyor belt can be customized according to the product size and product characteristics.

| Project |

Parameter |

| Model |

T-F20,T-F30,T-F50,T-F70,T-F100 |

| Laser power |

20W/30W/50W/70W/100W |

| Marking area |

110*110mm-300*300mm/600*600mm/(optional) |

| CCD visual range |

120mm (130 mega-pixels/500 mega-pixels (optional) +1.5 m conveyor) |

| Laser wavelength |

1064nm |

| Working accuracy |

0.002mm |

| Marking Depth |

0-0.5mm |

| Minimum font for marking |

0.15mm |

| Minimum character |

0.2mm |

| Marking speed |

0-7000mm/s |

| Operating system |

Win7 and Win10/32 bit and 64 bit |

| Laser source |

MAX (Raycus can be choose) |

| Repetition frequency |

20-100KHz |

| Cooling mode |

Air Cooling |

| Graphic format supported |

AI, PLT, DXF, BMP, DST, DWG, DXP |

| Environmental requirements |

Temperature: 10-35 ℃ ,Humidity: 5-75% |

| Working voltage |

220V 110V, 50/60 Hz |

| Applicable material |

All metal (Stainless steel, Carbon steel, Brass, etc.) and some plastic (ABS, PVC, PES, ETC.) |

| Optional Accessories to Purchase |

D80 Rotating Shaft/ D57 Small Chuck/2D Table (X.Y direction)/ Cutting Fixture |

| Net weight/gross weight (KG) |

140KG / 168KG |

| Machine dimension |

800*750*16500mm (L*W*H) |

| HS Code |

8456110090 |

Product Advantages

The visual laser marking machine is an innovative device in modern manufacturing, combining laser marking technology with advanced visual recognition systems. This integrated technology brings many advantages to the production process. The following is a detailed introduction to each of its advantages:

1. High-precision marking – Positioning accuracy: The visual system has high-resolution image capture capabilities, which can accurately locate the position and characteristics of the marked object, even on workpieces with irregular surfaces or complex shapes, and can ensure the accuracy of marking. – Delicate marking: Laser marking technology can achieve extremely delicate marking effects such as patterns, texts and barcodes, ensuring the clarity and readability of information, especially in industries that require micron-level requirements. This is particularly important.

2. Automatic alignment function – Real-time adjustment: The visual system can automatically identify the position and orientation of the product, align and adjust in real time, and reduce errors caused by manual intervention. This is very important for batch production with different product shapes. – Adaptability: Whether it is a fixed product or a mobile product, the visual laser marking machine can quickly adapt, reducing adjustment time and improving production efficiency.

3. Flexibility and applicability – Compatibility with multiple materials: The visual laser marking machine can efficiently mark various materials (such as metals, plastics, etc.), with strong adaptability and can meet different manufacturing needs. – Diverse marking content: The equipment can be used to mark complex patterns, QR codes, barcodes, serial numbers, etc., to meet the identification needs of various industries, especially in product traceability management.

4. High speed – Fast operation: The laser marking process is faster than other traditional marking methods (such as screen printing, mechanical engraving, etc.), especially in large-scale production, it can significantly shorten the production cycle and improve the efficiency of the production line. – Continuous operation capability: The visual laser marking machine can still maintain high-speed and stable marking performance under long-term continuous operation, which is suitable for high-volume industrial needs.

5. High-quality marking effect – Wear resistance: The non-interference nature of laser marking prevents the mark from wearing and fading in subsequent use, and can provide a lasting mark for the product. – Aesthetics: The marking effect is usually very beautiful and exquisite, which can significantly improve the appearance quality of the product and increase market competitiveness.

6. Environmental protection and safety – No pollution: No chemical materials such as ink and solvent are required during the marking process, which reduces pollution to the environment and reduces potential safety risks. – Safety design: Equipped with safety protection devices to ensure the personal safety of operators during use, in line with higher industrial safety standards.

7. Non-contact marking – Reduced risk of injury: Laser marking is a non-contact processing, whether on hard surfaces or on fine molds, it avoids surface damage that may be caused by direct contact.

8. Simple maintenance – Reduced maintenance costs: The structural design of the visual laser marking machine facilitates users to perform regular maintenance and cleaning, reducing downtime caused by equipment failure. – Technical support: Provide comprehensive after-sales service and technical support to ensure that operators can solve problems quickly.

9 Economical – Cost-effectiveness: Despite the high initial investment, the high efficiency, low maintenance cost and long-lasting marking effect can significantly reduce the production cost per unit product after long-term use, providing enterprises with a higher return on investment. – Improve market competitiveness: Efficient, environmentally friendly and beautiful production methods can enhance the market image of enterprises, attract more customers and increase sales.