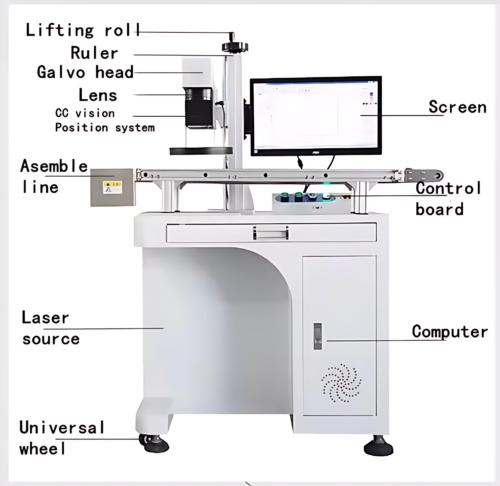

Based on the traditional marking machine, a high-pixel CCD camera is used to locate the current position of the product, and the position information of one or more products collected in real time is transmitted to the marking control card through the computer in order to achieve precise marking.

The visual positioning and marking system realizes rapid positioning, marking multiple products at a time, and can also carry out automatic assembly line feeding, and then perform visual positioning and marking after positioning, saving labor, improving work efficiency, and easy to realize automatic production compatible with multiple products The assembly line saves a lot of cost for labor.

Compared with the traditional laser marking machine, the marking interval is faster, saving 3-5 times the time of handling the product, and the position accuracy is higher. With its unique positioning system, the CCD laser marking machine is especially suitable for the super-fine processing market, handicrafts, IC electronic parts, PPC circuit boards and other polymer materials surface marking.