How does a fiber laser marking machine mark different materials?

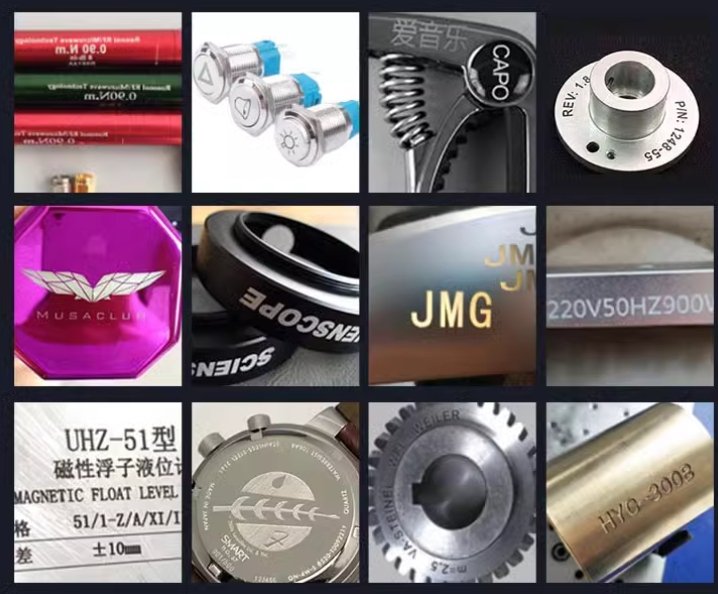

In today’s highly competitive market environment, the accuracy, durability, and aesthetics of product marking are of utmost importance. The fiber laser marking machine, with its superior performance, can achieve excellent marking effects on various materials. Here are detailed case studies of the fiber laser marking machine being used on different materials.

## I. Metal Materials: Precise Traceability of Auto Parts

The automotive manufacturing industry has extremely high requirements for the marking of parts. It not only needs to be clear and long – lasting but also meet the traceability requirements. A well – known automotive manufacturing enterprise uses a fiber laser marking machine to mark the engine block.

As the core component of a vehicle, the engine block is mostly made of cast iron or aluminum alloy. The fiber laser marking machine uses a high – energy – density laser beam to instantly vaporize the metal surface, forming clear and permanent markings. The marking content includes product models, production dates, batch numbers, and traceable QR codes. Even in the long – term high – temperature and high – pressure working environment of the engine, the markings remain clearly distinguishable, providing strong support for the quality traceability and after – sales service of the vehicle.

After this automotive manufacturing enterprise started using the fiber laser marking machine, the traceability accuracy of parts increased from the original 90% to over 99%. This has greatly improved production management efficiency and reduced quality problems caused by unclear markings.

## II. Plastic Materials: Personalized Customization of Electronic Product casings

The electronics market pursues personalization and a sense of fashion. The plastic casings of electronic products have become a stage for the fiber laser marking machine to showcase its creativity. An electronics production company designs markings for the casing of its new mobile phone.

Mobile phone casings are usually made of high – strength engineering plastics. The fiber laser marking machine forms exquisite patterns and text on the plastic surface by precisely controlling the laser energy and pulse frequency. For example, unique brand logos, personalized patterns, or limited – edition numbers are printed on the back cover of the mobile phone. After marking, the aesthetics of the mobile phone casing is significantly enhanced. Moreover, due to the tight combination of the laser marking and the plastic material, the abrasion resistance is good, and the markings are not easy to fall off even after long – term use and friction.

Once this mobile phone with fiber – laser – marked personalized customization was launched, it was warmly welcomed by consumers, and the product sales increased by 20% year – on – year.

## III. Glass Materials: Anti – counterfeiting Markings for High – end Liquor

In the liquor industry, especially for high – end liquors, anti – counterfeiting is of vital importance. A famous winery selects a fiber laser marking machine to apply anti – counterfeiting markings to its wine bottles.

Glass materials are hard and transparent, with extremely high requirements for the clarity and aesthetics of markings. The fiber laser marking machine forms high – resolution anti – counterfeiting markings on the glass surface by focusing the laser beam to produce a slight etching effect. These markings can be the winery’s exclusive patterns, anti – counterfeiting QR codes, or product batch information. Since the laser marking is a micro – etching on the glass surface and integrates with the glass material, it is difficult to copy and tamper with, effectively enhancing the anti – counterfeiting performance of the product.

Since the adoption of the fiber laser marking machine for anti – counterfeiting markings, the market share of counterfeit wines of this winery has dropped significantly, and consumers’ trust in the brand has increased remarkably.

## IV. Ceramic Materials: Demonstrating the Quality of Sanitary Ware Products

Ceramic sanitary ware products focus on the display of quality and brand image. A well – known sanitary ware brand uses a fiber laser marking machine to mark products such as ceramic toilets and washbasins.

The surface of ceramic materials is smooth, and traditional marking methods may have problems with insufficient adhesion. The fiber laser marking machine uses the thermal effect of the laser to form firm and beautiful markings on the ceramic surface. The marking content includes brand trademarks, product models, specifications, and quality certification marks. After laser marking, the overall quality of the ceramic sanitary ware products is enhanced, and the markings are highly durable. Even after long – term use and cleaning, they will not fade or fall off.

After this sanitary ware brand started using the fiber laser marking machine, the brand image of its products in the market has been further enhanced, the product price has increased to some extent, and the market competitiveness has been significantly strengthened.

In conclusion, the fiber laser marking machine, with its outstanding performance on different materials, brings more possibilities for product marking in various industries. Whether it is precise traceability, personalized customization, or anti – counterfeiting requirements, the fiber laser marking machine can handle them perfectly, helping enterprises enhance product value and market competitiveness.